Laser Beam Shutter

The LS- range of laser beam shutters are combined shutters and beam dumps designed to be driven by a safety control system such as the Lasermet’s Interlock controller for use as a means of shutting down the laser beam automatically during unauthorised access, or manually when the beam is not required.

The shutters will not open unless power is supplied. When power is supplied a yellow LED lights to indicate that power is present. A green LED will also light indicating that the shutter is fully closed. To open the shutter the green button must be pressed. The green LED will go out and an orange LED will light indicating that the shutter is fully open. The shutter can be closed by pressing the red button or by cutting the power.

The shutter is fail-safe and gravity operated so any loss of power will cause the shutter to close without reliance on springs or any other device.

Intelligent design results in low current consumption. This increases the number of shutters which can be run from the same power supply and keeps the shutter cool enough for use as a beam dump when closed.

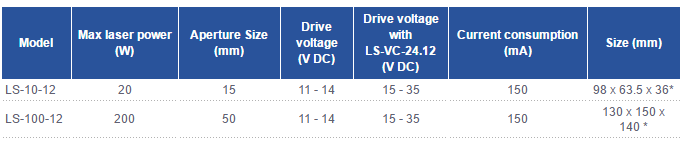

LS-10&LS-100High-Intensity Laser Shutters

LS-20 High-Intensity Laser Shutters

It has been designed to form part of a high-integrity safety system and features a gravity-close blade and force-disconnect proving contacts. When closed, the shutter deflects the incoming laser beam onto an internal beam dump where the energy is converted to heat which is dissipated in the aluminium casing of the shutter. When the shutter is open, the laser beam passes through the shutter without interruption.

LS-200 Laser Shutter – The “Thunder Shutter”

The LS200 Laser Safety Shutter is designed to prevent accidental exposure to potentially harmful laser beams.

When the shutter is open the laser beam passes in clear air through the shutter. When closed, the shutter deflects the incoming laser beam out of a separate port to an appropriate beam dump which must be fitted.

The equipment comprises of the LS-200 shutter with a power / communications cable and fixing nuts. The air cooled beam dump is a separate item but can be supplied as a complete set – shutter and beam dump. Users may wish to use a separate beam dump of higher capacity for use with a mirror blade and higher powered lasers.

The shutter uses a gravity close blade and force-disconnect proving contacts and is designed to form part of a high-integrity safety system.

A SIL3 dual version is also available which, when correctly wired with the Lasermet Interlock® Controller System can provide a safety Interlock® which meets Safety Integrity Level 3 to EN 61508 and ISO 13849-1 Performance Level ‘e’.

The shutter has a Ø50mm aperture.

LS-200 Standard and LS-200 SIL 24 laser shutters

·Gravity close blade

·Range of blade options

·Three control options

Optional beam dumps: Air cooled or water cooled

Safety rated options:

·LS-200 (Standard) EN ISO 13849-1 PL ‘c’

·LS-200 SIL-24 EN ISO 13849-1 PL ‘e’ IEC 61508-1 SIL 3

Power Density

Typically the LS-200 standard shutter using a stainless steel blade can handle 100W based on a 10mm beam diameter.

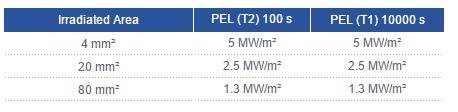

The PEL ratings below are for a standard stainless steel blade.