Laser Safety Window- Laser Safety World©

Laser Safety Window- Laser Safety World©

Laser Safety World© windows are manufactured with material of PMMA, compliant with European laser safety standards EN207, and are provided with high level of protection from laser radiation. High optical density(OD) and visible light transmittance(VLT), the windows have no optical distortion and are not easy to scratch. It measures 1280x1000x5mm of one piece of laser safety window, and custom-cutting, punching, chamfering, marking and anti-static are available. Laser Safety World© windows are widely applied to many areas: laser manufacture, scientific research, laser alignment system, medical and cosmetic facilities.

Laser Safety Film, kind of PET film on which are coated with a variety of metal oxides, provides protection from laser radiation of wavelength 780-3000nm by absorbing and reflecting. It is wearable, scratch-resistant, explosion-proof and easy to clean. This protective film can be cutted at any size or shape and attached on any material surface, and can also be used as single, double or multi-layer to provide high level of optical density.

Standards and Test:

Laser Safety World© windows are tested based on standards EN207&EN167, and are compliant with CMA and ilac-MRA, accreditation system which have been integrated to international mutual recognition. It means the Laser Safety World© windows are also compliant with CE standards, and meet the threshold of European market.

Selections: please read the following table.

*OD (optical density) is the amount of light attenuated by the lens of different particular wavelength that is being measured, e.g.OD4 means a light transmittance of 1/10000, and so on. For more details of OD value of each particular wavelength, please refer to the test report.

*VLT(visible light transmittance) is the amount of visible light(400-700nm) that can pass through the lens of a pair of glasses. More informally, it means the clearness of the lens of glasses, the higher the VLT value, the clearer the glasses.

|

P/N |

Application |

OD |

VLT |

Photo |

|

WAB-D5T35 |

UV, Blue laser, Green laser, Wavelength 532nm. |

OD7+@190-350nm |

35% |

|

|

WAB-D6T30 |

190-550nm |

6+ |

30% |

|

|

WAC-D5T35 |

UV, Red laser, Wavelength 630nm, 660nm |

OD6+@190-280nm OD5+@280-383nm OD4+@383-400nm OD3+@600-630nm OD4+@630-720nm |

35% |

|

|

WAD-D5T60 |

Fiber, IR, wavelength 1064nm, and low light environments |

OD7+@190-280nm |

60% |

|

|

WAD-D8T55 |

820-1100nm |

8+ |

55% |

|

|

WABD-D5T35 |

Fiber IR, laser welding/cutting/ cleaning, and wavelength 532nm &1064nm. |

OD7+@190-280nm |

35% |

|

|

WADEF-D5T40 |

1540nm |

OD7+@190-280nm |

40% |

|

|

WDEF-D6T30 |

800-1700nm |

6+ |

30% |

|

|

WADE-D4T35 |

Fiber IR, Wavelength 1064nm, laser welding/ cutting/ cleaning |

OD7+@190-400nm |

35% |

|

|

WCO2-D5T75 |

CO2 laser |

OD6+@10600nm |

75% |

|

| Laser Safety Film |

UV,Fiber IR, 1064nm,1319nm, 1550nm,2100nm, 2780nm,2940nm |

OD5+@190-360nm OD3+@900-1100nm OD4+@1000-1200nm OD5+@1200-1800nm OD4+@1800-1900nm OD3+@1900-2300nm OD2+@2300-3000nm |

50% |  |

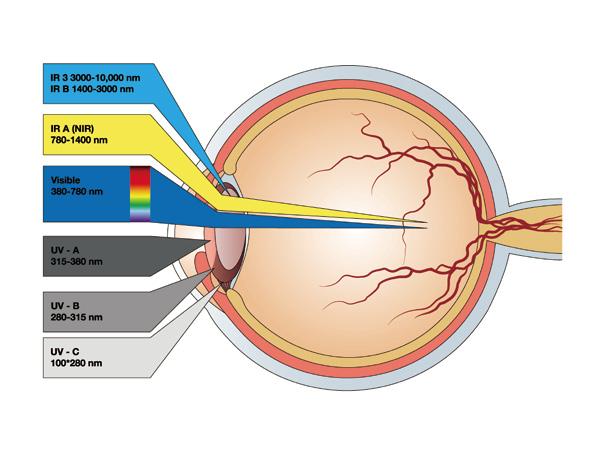

Hazards of laser radiation to human eyes:

The damages of laser radiation to eyes will cause the photokeratitis, corneal coagulation, carbonization and perforation, lens cloudiness, visual dysfunction “flash blindness” and retinal coagulation, bleeding, and rupture. When the visible light with high intensity or near-infrared light enters the eye, it can pass through the human eye refractive medium and focus light onto the retina. At this time, the laser energy density on the retina reaches to thousands or even tens of thousands of times, and a large amount of light energy is instantly focused on the retina, causing the temperature of the photoreceptor cell layer of the retina to rise rapidly, resulting in photoreceptor cell coagulation degeneration necrosis and loss of photosensitive function.